Basic Information Basic Information |

|

| Company logo |

|

Company Name |

CHEOMDANLAB INC. |

|

| address |

110 BI Center, Chosun University 50, Cheomdangwagi-ro 208beon-gil, Buk-gu, Gwangju |

homepage |

www.cheomdanlab.com |

|

| Phone number |

062-971-1238 |

Fax number |

062-971-1239 |

|

| Participation Year |

2019,2020 |

Booth number |

|

|

| exhibition |

LED&OLED Materials/Parts/Equipment Zone |

Main exhibition items |

Optical Diffusion Materials and Parts |

|

|

About Us About Us |

|

Cheomdanlab inc. is a company specializing in optical materials and parts located in Gwangju Metropolitan City.

Based on nanotechnology, we are developing polymer materials for special wavelength light sources and manufacturing optical diffusion components through process technology.

With a constant spirit of challenge and continuous R&D, we have the ability to respond to rapid market changes and new technology development, and we will provide differentiated services through customized production and carefully analyze customer requirements.

|

Item description Item description |

|

“Transparent fluoride polymer material.“ - Essential materials for commercialization of UVC-LED chips protect chips from external heat, moisture, physical shocks, etc. to secure product stability and life and improve light efficiency. - material (stability, heat resistance, permeability) that can be secured without any external deformation, such as crack, or external deformation even after prolonged exposure to UVC energy (stability, heat resistance, permeability). - Thermal stability in the Deep UV area and high binding energy compared to silicon materials for conventional LEDs using high-molecular fluoride materials.

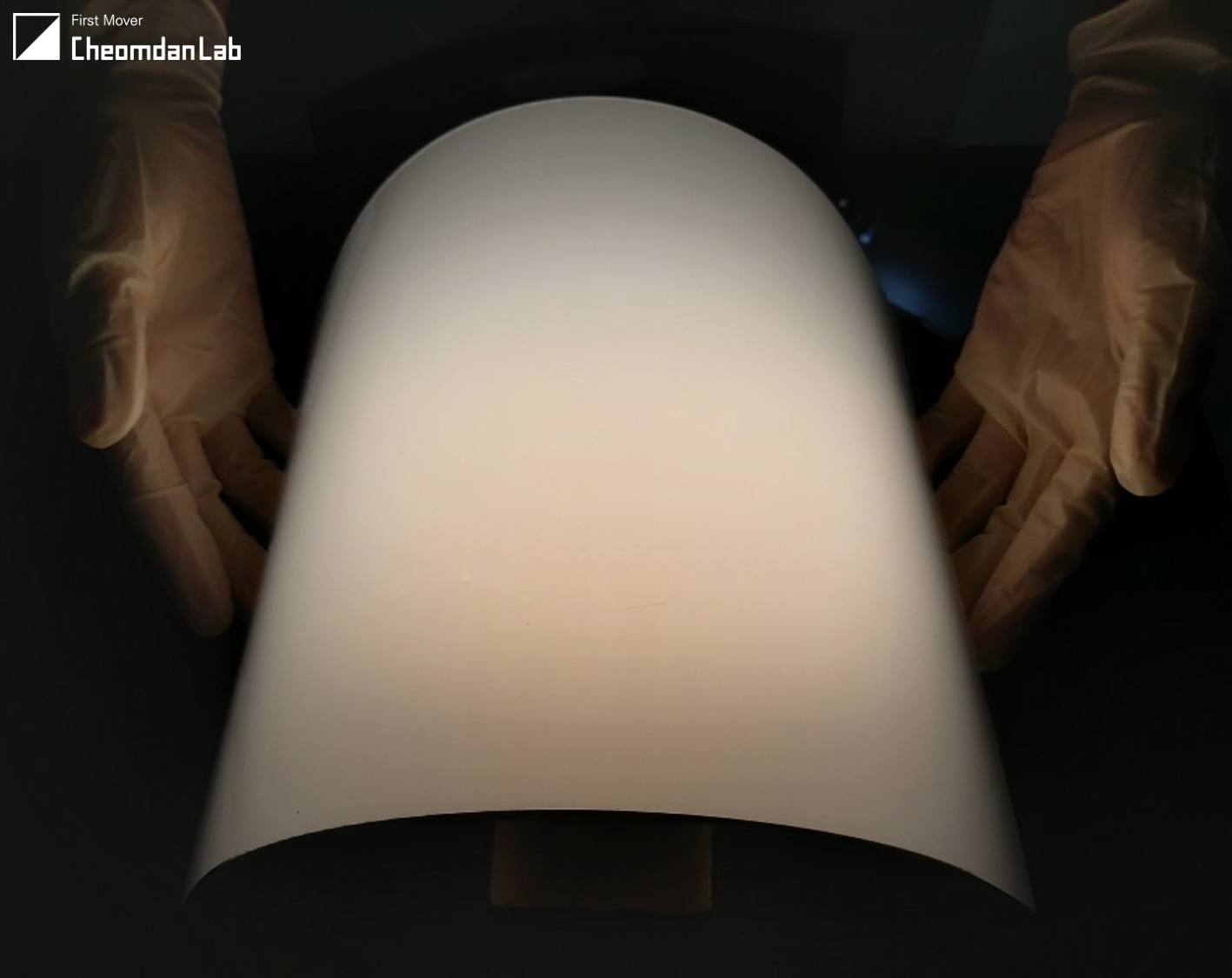

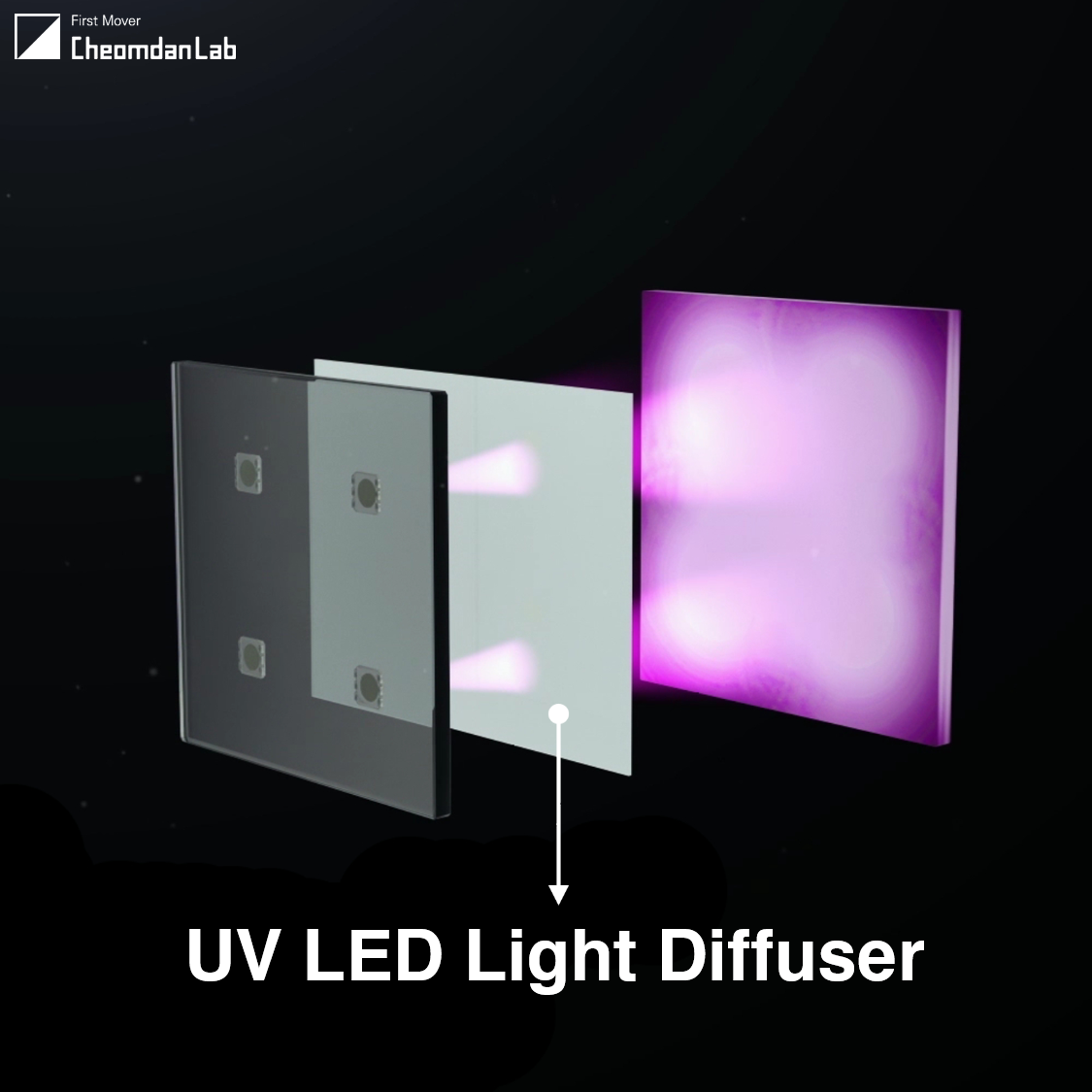

“UV-LED Light Diffusion Plate” - Light diffusion plates/sheets with transmittance rate and scattering optimized for the product of the demand source by applying the scattering method that occurs as light passes through the air pore. - Various optical characteristics can be implemented in client products by utilizing air pore layer control technology, air pore layer dispersion technology, and coating layer solution manufacturing recipe. - Unlike existing competitor parts, which are manufactured in the form of plastic extrusion that can only be applied to visible light wavelengths, the company has a competitive edge. Manufacture of light diffuser plate optimized for light source using one time coating on the base substrate(Glass, Plastic)

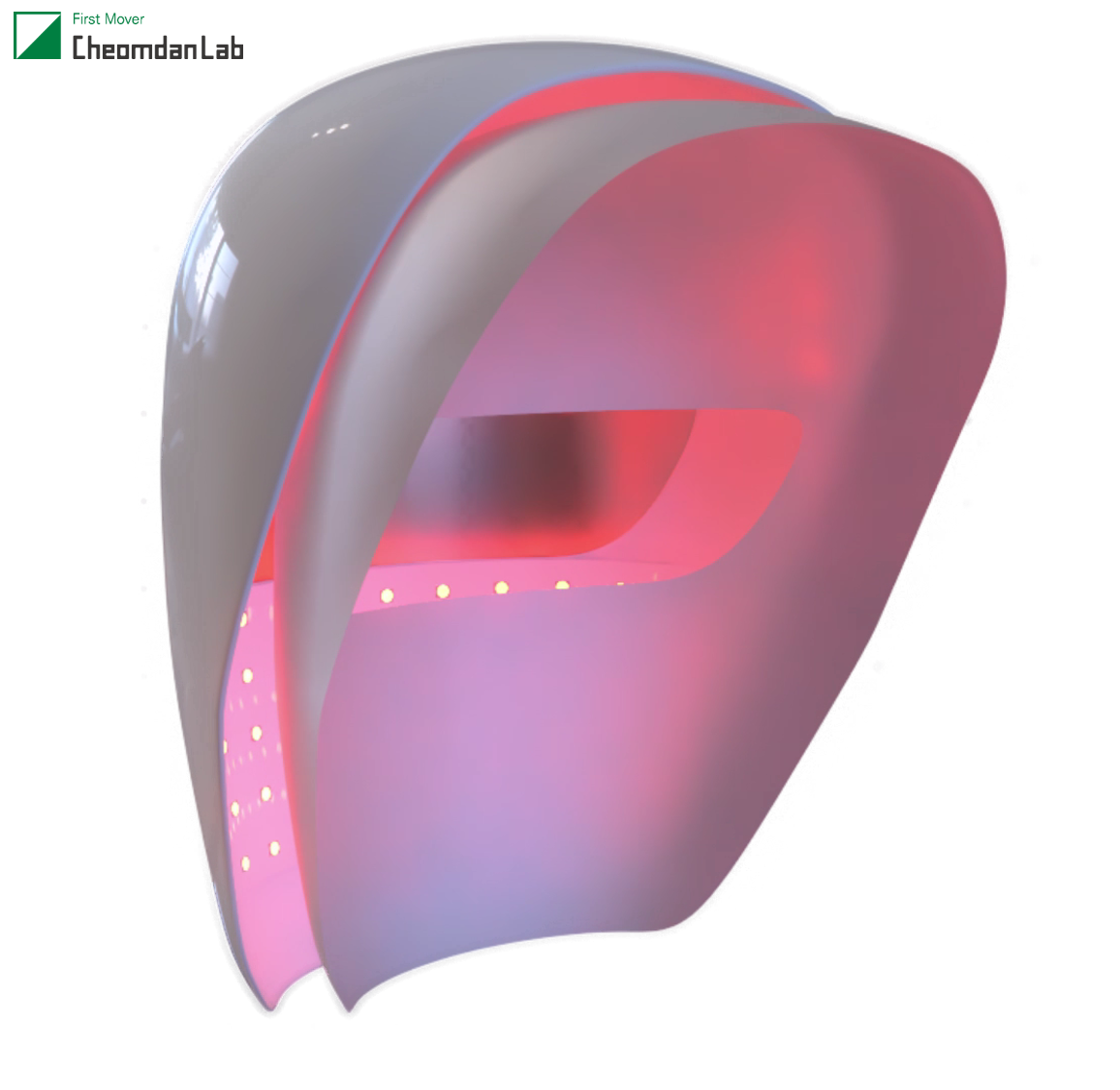

“Integrated module of light diffusion structure” - Integrated module of photo-diffusion structures with developed polymer materials. - Enables the transmission of energy unique to light sources without changing wavelengths from UV to visible light areas. - Uniform energy transfer is possible through the spread of light sources. - Applicable to various applications (medical,beauty, etc.)

|

5

5

|

4

4

|

3

3

|

2

2

|

1

1

|

|

|

[More View]

|

|

|

| |

|